Aircraft Component Manufacturing

Special processes such as resistance spot welding and cold expansion are approved by customers, and each single item is completed into optimal assembly products using skilled assembly technology, and then produced and delivered to domestic and foreign companies.

-

Contract

-

Assembly

Planning -

SUB/Final

Assembly -

Part Fabrication

-

Paint

-

Quality

Control -

Packing

-

Delivery

- Assembly Business

-

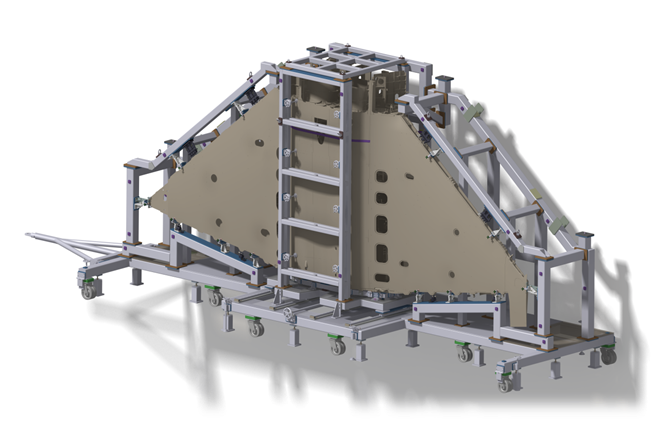

- Rotary Wing Helicopter SUB, FINAL Assembly (BELL 412, KUH, A-64E)

- Boeing P-8A Raked Wing Tip Assembly / B767 ATB Rib & S48 Frame / Triumph B767 Fixed Trailing Edge Assembly

- Triumph G-V Leading Edge Assembly / Lockheed Martin C-130 Engine Nacelle Assembly / T-50 Canopy Assembly